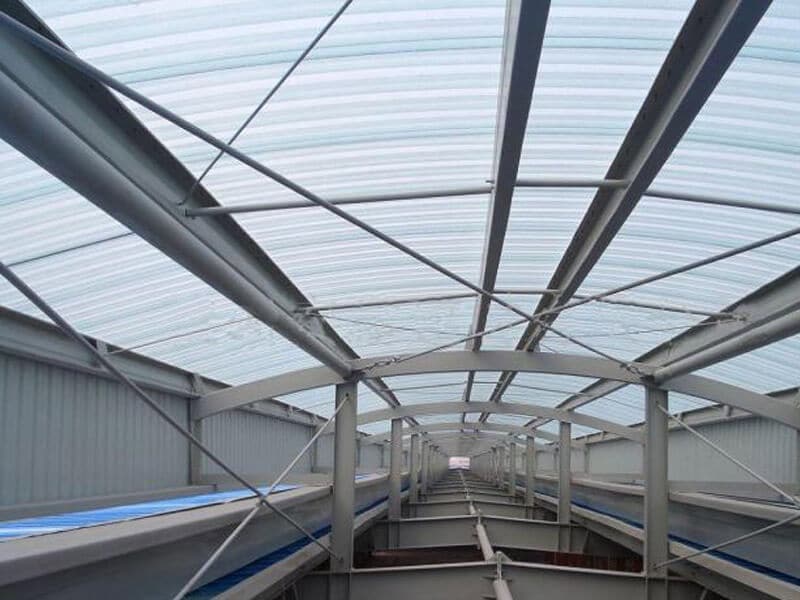

FRP sheets for cooling tower

FRP Cooling tower

FRP sheets for cooling tower

Zhongsheng FRP cooling tower panels are mainly intended for the Cooling tower.

Fiber Reinforced Polymer (FRP) panels have become a game-changer in the cooling tower industry. These anti-corrosion panels provide numerous benefits that significantly enhance the performance and efficiency of cooling towers while reducing costs and simplifying the installation process.

We’ll explore the advantages of GRP panels in cooling tower projects and the benefits of double-sided gel coats and flame-retardant grades.

Benefits of FRP Panels in the Cooling Tower Industry:

Time and Cost Efficiency:

One of the most significant advantages of using our panels is reducing project completion time. Implementing these anti-corrosion panels can expedite the finishing process by up to 70%, leading to more convenient installations and a faster return on investment. Furthermore, the improved product quality offered by FRP panels lowers production costs by reducing the need for constant maintenance and repairs.

Enhanced Product Quality:

The fiberglass panels enhance the overall quality and performance of cooling towers. Their corrosion-resistant nature prevents structural deterioration, which can lead to reduced efficiency and increased downtime. With FRP panels in place, cooling towers can maintain optimal performance for extended periods, ensuring uninterrupted operation and increased end-user satisfaction.

Easy Installation:

The lightweight and versatile nature of the panels makes them incredibly easy to install. This reduces the time needed for installation and minimizes the labor required, ultimately reducing the project’s overall cost. Additionally, they can be customized to fit any design, making them an ideal solution for various cooling tower configurations.

Double-sided Gel Coat:

The panels/sheets are highly recommended to be produced with a double-sided gel coat. This added layer of protection further enhances the panels’ durability and resistance to harsh environmental conditions. As a result, cooling towers fitted with double-sided gel coated panels will have an extended service life, ensuring a higher return on investment.

Flame Retardant Grade:

FRP panels can be designed with an ASTM E84 A-grade flame retardant rating to improve the safety and performance of cooling towers. This feature reduces the risk of fire hazards, ensures a safer working environment, and gives facility managers and operators peace of mind.

Incorporating FRP panels into cooling tower projects can lead to significant benefits, such as reduced finishing time, lower production costs, and improved product quality. By opting for FRP panels with double-sided gel coats and high flame retardant grades, cooling tower manufacturers and end-users can experience even more excellent performance, safety, and durability advantages. Don’t hesitate to switch to FRP panels for your next cooling tower project – the benefits are clear.

Application

Cooling towers